Mission-critical warehouse software Victaulic modernised according to NextGen architecture

- 2 November 2022

- 5 minutes

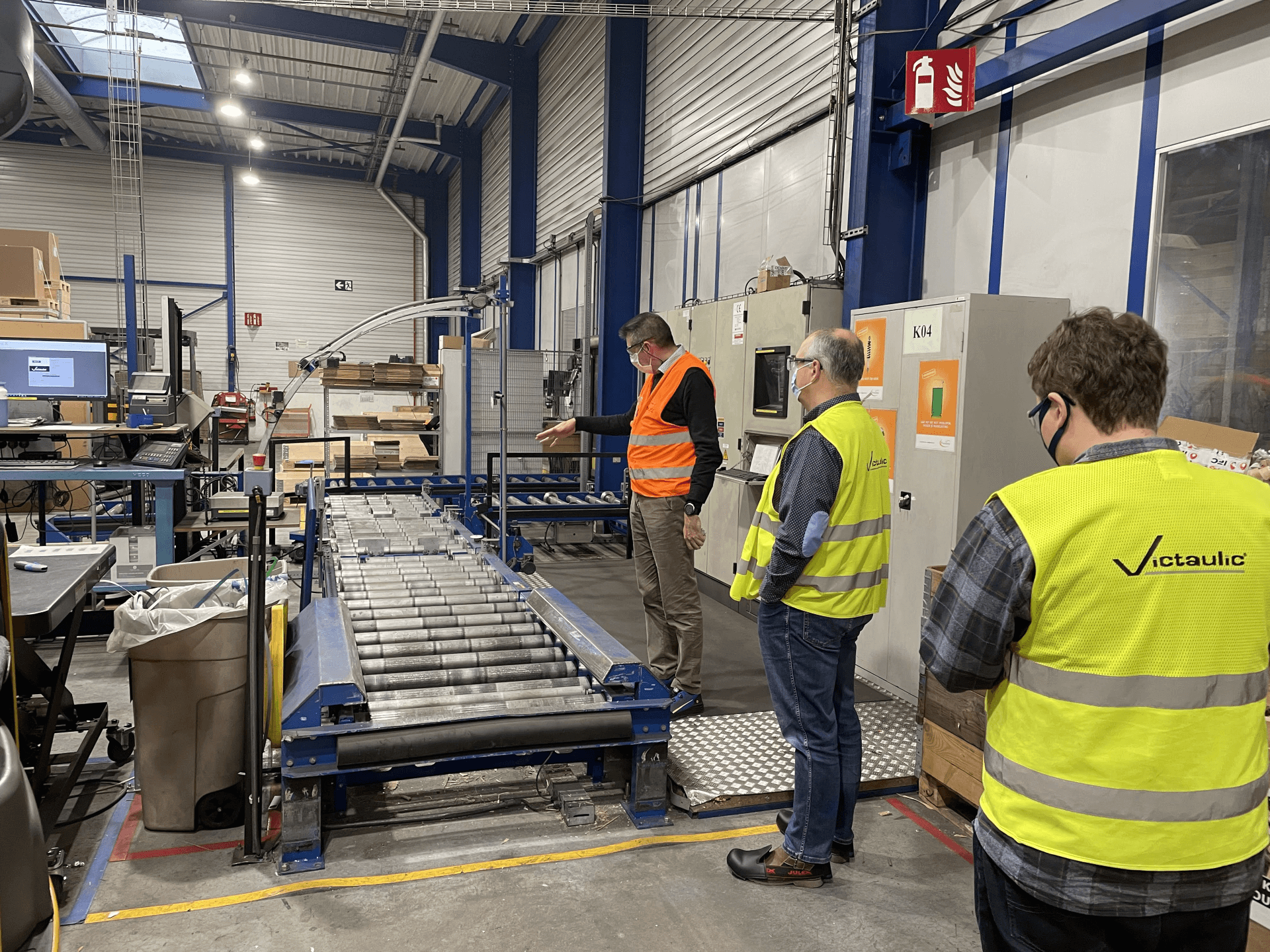

For years, Victaulic had been working with the same Warehouse Control Software for their distribution centre in Belgium. A security problem was the reason to perform a security update and modernise the entire user interface, application and database. An ICT Group logistics software team worked in close cooperation with Victaulic and successfully completed the migration within six months.

Staying ahead of problems

Pascal Fiers, operational director EMEA at Victaulic, has been working with the company since 1989 and has helped set up several sites. In 1999 he participated in the first industrial automation project and he was also directly involved in a very recent project: "The logistics software for our warehouse in Nazareth (Belgium) had been running as desired for years. But it was also clear that we had to keep up with the times and improve systems, for instance by raising the security of the servers to a higher level. This was a good moment to modernise the entire application. After all, You want to stay ahead of potential problems and this was an excellent opportunity to tackle everything all at once."

The shop had to remain open'

"ICT Group had been managing the application since 2015, so it was obvious that I talk to them about the necessary steps. Our IT department worked together with René Hassfeld, project manager at ICT Group, to determine the scope of the project. Addressing the security risks was done by modernising the entire application, as opposed to making the old application secure. Just addressing parts of the old application felt more like sticking plasters, but now we have a 'next generation' API Service and Application Server in C#.NET. An important condition was that 'the shop' would remain open during the process. We absolutely could not afford to shut down the distribution centre and the logistics processes, not even temporarily."

Two systems working side by side

"The fact that the documentation was outdated made it difficult to fully map the functionality. ICT Group solved this problem by using reverse engineering and its own simulator to follow the old software. Two systems ran side by side, the old and new screens of the user interface, which allowed us to see exactly what went right and what went wrong, and it showed us which adjustments were required for error-free operation. We also used the simulator of the crane supplier, and this helped us to completely verifify all phases and scenarios of the logistics process, from inbound at the I-point to full pallet output and quality control, and as a result we could also improve the last aspects at a more detailed level."

"We are very satisfied with the cooperation with the ICT Group software team. The team work was exemplary."

- Pascal Fiers, operational director EMEA bij Victaulic

Result

"The entire project was executed perfectly within the timeline, and everything went smoothly right from the start. We made excellent progress thanks to performing a lot of intermediary tests and reporting directly on this. In addition, I must say that we also had a lot of knowledge about the application and this greatly promoted the interaction between the teams. We could continuously communicate with each other on the same level. After the phased delivery in May of this year, we only had three or four minor updates. ICT Group is of course still monitoring and managing the application. The added value of ICT Group is mainly reflected in their approach and their domain knowledge of distribution centres and logistics. As a result, we have been able to modernise our logistics systems without substantial loss of time."

Future-proof

"It is certainly worth mentioning that their team found a lot of smaller bugs during the process which we ourselves had not noticed before. These were things that we rarely, if ever, had problems with in practice, but it does say a lot about how deeply their software developers have immersed themselves in our application and logistics. This gave us unexpected new insights for all kinds of extra optimisations. There’s no doubt that there will be additional changes within the supply chain in the future, but with what is running now, we can continue to optimise and further increase our productivity. The ICT Group team is a team to continue with. Their way of working has definitely led to the intended result: on time, without disruption to our logistics processes, and a modern solution that’s future-proof. That's exactly what you want."

About Victaulic

Victaulic is the founder, developer and manufacturer of connection systems for grooved tube couplings and mechanical pipe connection solutions. The company is headquartered in Easton, Pennsylvania USA, and has 15 large manufacturing facilities, 28 sites and more than 3600 employees worldwide.

Victaulic creates technologies and provides engineering services for the most complex pipeline challenges. By combining and controlling engineering, research, product development and production from within the organisation, Victaulic ensures quality in all its global production facilities. Their solutions enable people to work faster, while increasing safety, ensuring reliability and maximising efficiency.