Patrick has only worked at Raster for four months, but can already say that he feels right at home in Barendrecht. As a member of a close-knit team he works on great projects, and he can even cycle to work.

About ten years ago, at the end of his studies in electrical engineering, Patrick built his first 3D printer. "What particularly appealed to me is that a 3D printer allows you to design your own objects and produce them on a small scale," he says. "During my studies, I regularly needed parts, which I then had to manufacture myself somehow, usually from wood or plexiglass. That had quite a high hobby content. I realised that I would achieve much better results with a 3D printer."

Open source community

3D printing was still in its infancy in those years, Patrick recalls. "You couldn’t buy an off-the-shelf device anywhere, and there was no AliExpress to get parts easily." So he built his first 3D printer with parts he ordered from a printer fanatic on eBay. "I mounted all the parts onto a wooden frame, connected them to a set of electric motors and some circuit boards, and it already started to look like something. And the best part was, it worked!"

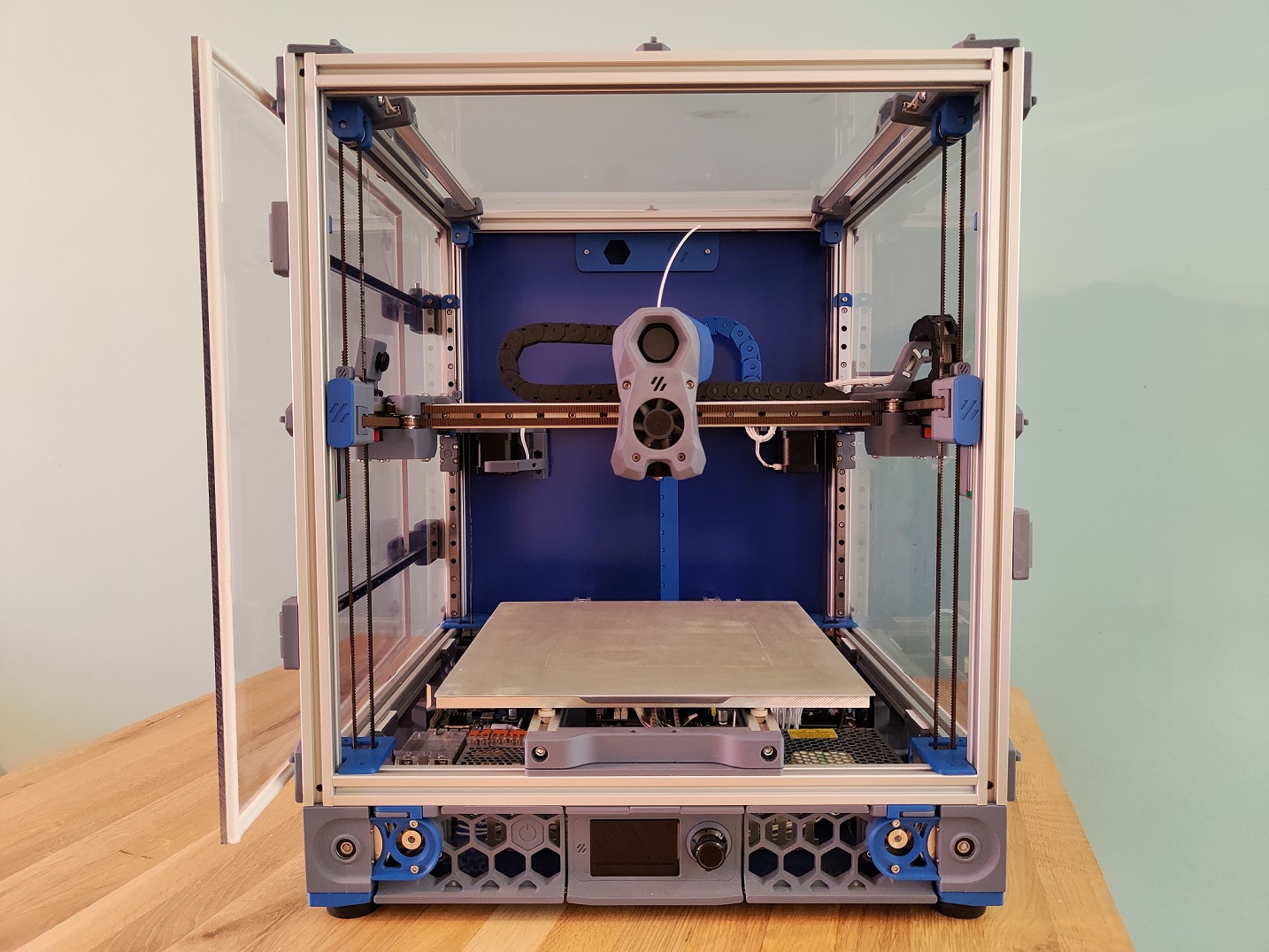

Since then, Patrick has built his fourth printer. "I came across an interesting open source community, which I joined. We share our knowledge and experience. This leaves me more time to immerse myself in design skills." This community is working on professional printers with the aim of creating high-quality prints on a plug and play printer.

"What particularly appealed to me is that a 3D printer allows you to design your own objects and produce them on a small scale."

Creativity

Combined with the necessary technical knowledge and curiosity, Patrick’s creativity comes in handy in his work for ICT Group, as well as in his passion for 3D printing. "I’m not easily satisfied, and sometimes that’s a tricky trait. As a result, I have to watch how I divide my time, and often I have to leave the printer disassembled in bits and pieces that I can print with it," he confesses. "In my job, you can't do that of course. That would become far too expensive."